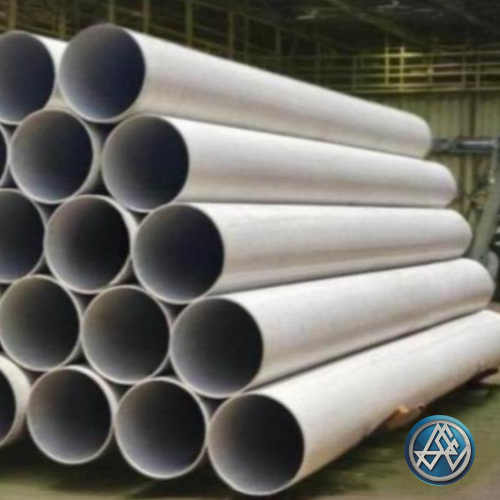

At Akash Steel Craft, we specialize in manufacturing Stainless Steel EFW (Electric Fusion Welded) Pipes & Tubes that serve a wide range of industries, including oil, shipbuilding, power plants, and natural gas. Our SS EFW pipes and tubes are made from austenitic chromium-nickel stainless steel, specifically designed to withstand corrosive environments and high temperatures, making them a top choice for demanding industrial applications.

Our SS EFW pipes and tubes are essential components in many key industries, including :

-

Oil and Gas Industry

-

Power Plants and Boilers

-

Shipbuilding

-

Filtration and Refrigeration Industries

-

Petrochemical and Refining Sectors

-

Offshore Industry

Manufacturing Range

We offer a wide range of sizes and thicknesses for our SS EFW pipes and tubes:

-

Size Range: 6” NB to 100” NB

-

Thickness: 2 mm to 60 mm

-

Specifications: ASTM A-358 CL – I, II, III, IV, V & A-778

Key Features of SS EFW Pipes & Tubes

Our SS EFW pipes and tubes offer several distinct advantages that ensure reliable performance, including:

-

Durability: Built to last in the toughest conditions.

-

High strength: Capable of withstanding high-pressure environments.

-

Effective functionality: Designed for optimal performance.

-

Sturdy construction: Manufactured to provide structural integrity.

-

Corrosion resistance: Highly resistant to rust and corrosive materials.

-

Dimensional accuracy: Engineered to precise specifications for seamless fit.

Our manufacturing process is a combination of advanced technologies and industry expertise. We use a 1600MT press brake machine, multiple rolls bending machine, and state-of-the-art welding installations for both internal and external welding. Here's a breakdown of our process:

-

Cutting edges of the stainless steel plate to size.

-

Pre-bending the plates.

-

Roll forming the material into pipes.

-

Pre-welding, followed by final welding with filler material.

-

Heat treatment on a continuous roller for enhanced durability.

-

X-ray testing and hydrostatic testing for quality assurance.

-

Finally, the pipes are sized, pickled, and passivated to ensure corrosion resistance.

All welders, welding operators, and welding procedures are fully qualified under the ASME Boiler and Pressure Vessel Code, ensuring top-notch quality at every step of production.

Our focus on quality and precision ensures that our SS EFW pipes and tubes meet the highest industry standards, making them an ideal choice for critical industrial applications.

.png)